Co-firing of biomass

Co-firing is the (partial) substitution of fossil coal by biomass in coal-fired power plants. Torrefied biomass offers the most cost-effective route to significantly increase the use of biomass as a renewable energy source and to reduce the CO2 footprint of industrial coal users.

Today most electricity and heat is still produced from coal. Blackwood believes that a significant contribution of the future renewable energy mix will come from replacing fossil coal with torrefied biomass, which will cause a major leap forward in the decarbonization of energy production. Leveraging the enormous installed base of current power and heat production assets and invested capital, torrefaction enables an affordable and fast substitution of fossil coal by biomass. Besides the aspect of existing infrastructure, biomass is a non-intermittent renewable energy source.

There is sufficient sustainable biomass in the world to turn it into the most significant and reliable source of renewable energy. However, biomass has poor fuel characteristics. It has a relatively low heating value, biomass is biological active and its fibrous structure makes biomass difficult to grind. This limits the extent to which biomass can be (co-)fired without significant investments into additional infrastructure in current pulverized coal power stations.

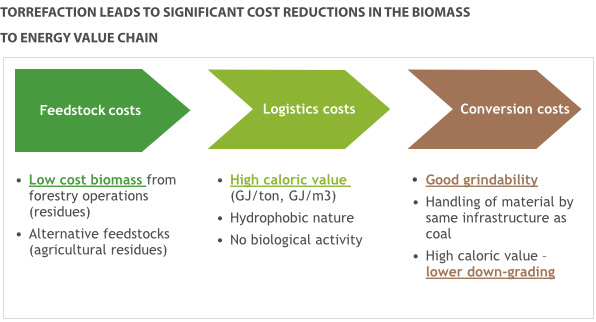

These limitations are eliminated when biomass is first torrefied. Upgrading the biomass through torrefaction makes it cheaper to transport, store and combust. Blackwood’s FlashTor® torrefaction technology delivers approx. 20% costs savings for utilities using torrefied pellets instead of white pellets. Furthermore, torrefaction enables far higher co-firing rates alongside fossil coal in existing power stations. It avoids the additional capital expenditures for biomass handling. In addition the de-rating of the electricty output associated with burning wood pellets is much smaller.

Case study: Co-firing of black pellets at Amer 9 power station

In November and December 2013, Blackwood’s predecessor Topell Energy delivered a total of 2,300 tons of black pellets for a large-scale co-firing test to the Amer power station of RWE Generation in the Netherlands. The torrefied pellets were successfully transported, handled, co-milled and co-fired to produce green electricity. The co-milling and co-firing took place at a rate of up to 25%. Critical items addressed during the test were dust formation, milling properties and burner stability. No adverse effect on milling and burning was detected in any of the tests. The trial therefore confirmed that high quality ‘biopellets’ can be produced and co-fired at large commercial scale.

To view a video of the pellet production at Topell Energy’s Duiven plant and the co-firing at the Amer power plant, please click here.