FlashTor® Technology

Blackwood Technology’s FlashTor ® technology is a unique process to produce torrefied biomass. FlashTor ® is a proprietary multi-stage process using a series of reactors to convert fibrous biomass feedstock into torrefied biomass. The volatiles released during the torrefaction process (torgas) are burnt in a lean gas combustor. The combustor provides the required heat for the torrefaction process and the pre-drying of the biomass. The final stage of the FlashTor ® system is a proprietary product cooling system.

Blackwood’s FlashTor ® technology is flexible with respect to the particle size and to the nature of the incoming biomass. Due to the multi-staged FlashTor ®-concept, the torrefaction process can be optimally controlled. This results in safe operation and the ability to always produce at the optimal process conditions. Consequently the unique and patented FlashTor® process results in optimal efficiency of the biomass torrefaction process. Efficiency, process controllability and flexibility are all essential cost drivers: keeping feedstock and processing costs as low as possible is crucial in a commodity fuel market.

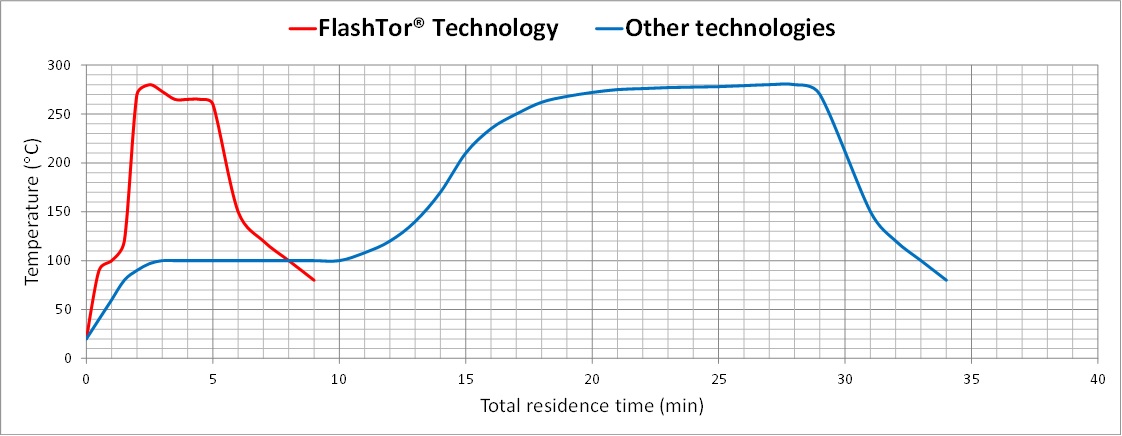

Compared to other torrefaction technologies, Blackwood’s FlashTor ® System stands for a much faster process. This decreases material hold-up in the system, reducing the size of the installation and leading to an unequalled control of the torrefaction process. The controllability of the process enables very precise and constant process conditions. As a result it is possible to produce at any desired torrefaction degree while ensuring a homogeneous product output.

Due to its small footprint and short residence times, the FlashTor ® System is a very scalable system. Furthermore, it can be easily integrated with standard drying systems, such as rotary drum and belt dryers, used in regular wood pellet plants. This makes the FlashTor ® technology the ideal technology for industrial scale torrefaction plants.

The FlashTor ® System is the only torrefaction technology in the world, which has been proven at industrial scale. The technology was first applied in a commercial scale demo torrefaction plant of Topell Energy in Duiven, the Netherlands. Torrefied pellets produced in this plant were successfully co-fired in several European coal-fired power plants and smaller biomass CHP systems.

For a video of the Duiven plant in operation and the co-firing of torrefied pellets at RWE’s Amer power plant, please click here.